Inevitable Measures to Prevent Mobile Robots Performance Degradation

Invest in yourself: ca. 3 minutes

Amidst the whirlwind of innovation and technological advancement in the realm of robotics, there exists a silent adversary – performance degradation. Mobile Robots (AGV&AMR) used in different environments, regardless of their advanced capabilities, face various problems and performance degradation when performing tasks after a certain period of time.

This degradation, often imperceptible at first, manifests across three crucial dimensions: hardware functionality, hardware condition, and software efficacy. According to this, it’s more important to regularly maintain a mobile robot system. This article delves deep into these dimensions of performance degradation, unveiling the hidden challenges that can impact even the most impeccably implemented robotic systems.

Predictive maintenance against the degradation of robot hardware

Picture a newly minted robot fresh from the production line - its movements are precise, and its responses sharp. Yet, with consistent use, wear and tear gradually take their toll. Hardware functionality degradation is inevitable. Without proactive measures, it leads to unexpected downtime and subpar performance, impacting productivity and efficiency significantly. The cost of such downtime can be astronomical.

Measure: Predictive maintenance can identify subtle signs of hardware issues before they escalate. This proactive approach not only optimizes the robot's performance but also extends its operational life, substantially reducing maintenance costs.

Regular Check-ups improve the condition of robot hardware

Maintaining a robotic installation isn't just about replacing components; it's about ensuring every part is in optimal condition. Overlooking this can lead to subtle yet significant performance degradation. An illustrative case in point is cleanliness. Accumulation of dust, dirt, and debris can impact sensors, motors, and other vital components.

Measure: Implementing regular cleaning procedures not only prevents functional deterioration but also preserves the accuracy and precision for which robots are esteemed. Just as we maintain the shine of a cherished possession through cleaning, similar care is imperative for robotic systems.

Regular adaptions to prevent software performance degradation

The software driving robotic operations is subject to its own form of performance degradation due to the dynamic working environment. Even minor shifts can lead to accumulative software errors that erode performance, causing costly errors, rework, and damaged products. Consider small navigation errors resulting from minor floor rearrangements, seemingly insignificant at first but detrimental when accumulated, leading to reduced accuracy and efficiency.

Measure: To mitigate this, it's crucial to implement continuous process updates and recalibrations. By adjusting the process to the changing environment, robots can maintain the precision they were originally designed for.

Conclusion

While successful robotic implementation is a significant milestone, sustaining this level of performance requires ongoing effort. Both performance degradation in hardware functionality and condition as well as software degradation represent the trio of challenges every robotics expert must anticipate. To optimize return on investment, organizations must shift from a reactive to a proactive maintenance approach. This involves adopting predictive maintenance strategies, implementing routine cleaning procedures, and consistently adapting processes to evolving demands.

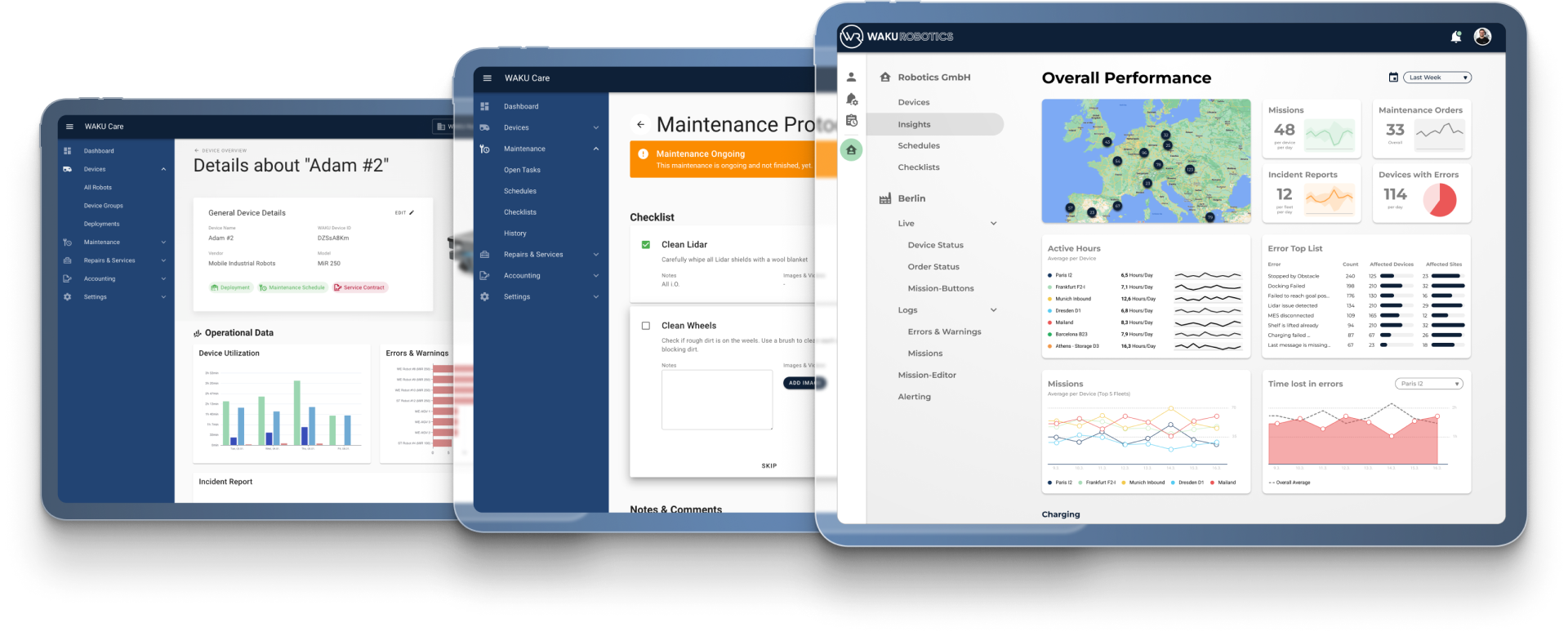

Encounter robot performance degradation with WAKU Platform

WAKU Platform steps in as a formidable ally, transitioning organizations from a reactive to a proactive maintenance mindset fighting against performance degradation. It isn't just a solution; it's a commitment to the enduring success of your robotic investments. By embracing innovation and adhering to the basics, the WAKU Platform ensures that brilliance achieved during implementation continues to shine brightly for the long haul.

Try the Care module of the WAKU Platform for free! Book your individual demo here!

WAKU Robotics supports you in choosing the right robot for your application. We take care of the procurement of the robots as well as the on-site test. Our WAKU Platform software helps you to operate the robots across manufacturers and to analyze the processes.

Contact WAKU